This document highlights the significant impact of high-alloy forged liners on the efficiency and cost-effectiveness of mining operations. Traditional metal liners, commonly made using casting technology, are subject to frequent wear and tear, requiring regular maintenance and leading to equipment downtime. However, Naipu Mining Machinery has developed a groundbreaking solution with its high-alloy forged liners, which combine material innovation and advanced forging technology to offer improved performance and durability.

These liners have been designed to reduce material defects, resulting in greater reliability and performance. Their optimized structure enhances processing capacity and reduces overall weight, which prevents overloads during operation. One of the major benefits of this technology.Innovative high alloy forged lining to solve mining problems is the extended service life of the liners. In practical applications, such as at a mine in Tibet, the high-alloy forged liners have more than doubled the service life from the original 4 months to over 7 months. This increase in lifespan directly correlates with a 99.7% boost in processing capacity, significantly improving the mine’s efficiency.

Customer feedback from the Tibet mine indicates that the new liners have reduced downtime by 3 days per year and are expected to save over 5 million yuan annually in maintenance costs. The introduction of these high-alloy forged liners provides an effective, stable, and economically beneficial solution to the mining industry’s long-standing challenges.

Liner service life is a key factor for efficient mine production

In the field of mineral processing, the life of the mill barrel liner directly affects the equipment’s operating efficiency and cost control. Every reduction in downtime can save millions in maintenance costs and improve the stability of production capacity throughout the year.

A semi-autogenous grinding mill in a mine in Tibet

Innovative high alloy forged lining to solve mining problems

Traditional metal liners are generally made using casting technology, but Naipu Mining Machinery breaks the convention and launches high-alloy forged liners through dual innovations of “materials + technology”. This liner uses a special forging process to reduce material defects and has higher reliability; it is also optimized to an equal-height structure, which improves processing capacity while reducing overall weight, effectively avoiding overload operation.

It also has five major highlights: the service life is greatly extended, which can reduce 1-2 downtimes per year and save 4-8 days; the material is strong and not easily deformed, making installation and disassembly easier.

In actual application in a mine in Tibet, the effect is remarkable. The original lining of the mine has a service life of 4 months, while the service life of the high-alloy forged lining of Naipu Mining Machinery has successfully exceeded 7 months. The processing capacity of a single set of linings has increased sharply from 897,600 tons to 1,792,600 tons, and the total processing capacity has increased by 99.7%, which has truly solved the industry’s problems and brought efficient and stable solutions to mine operations.

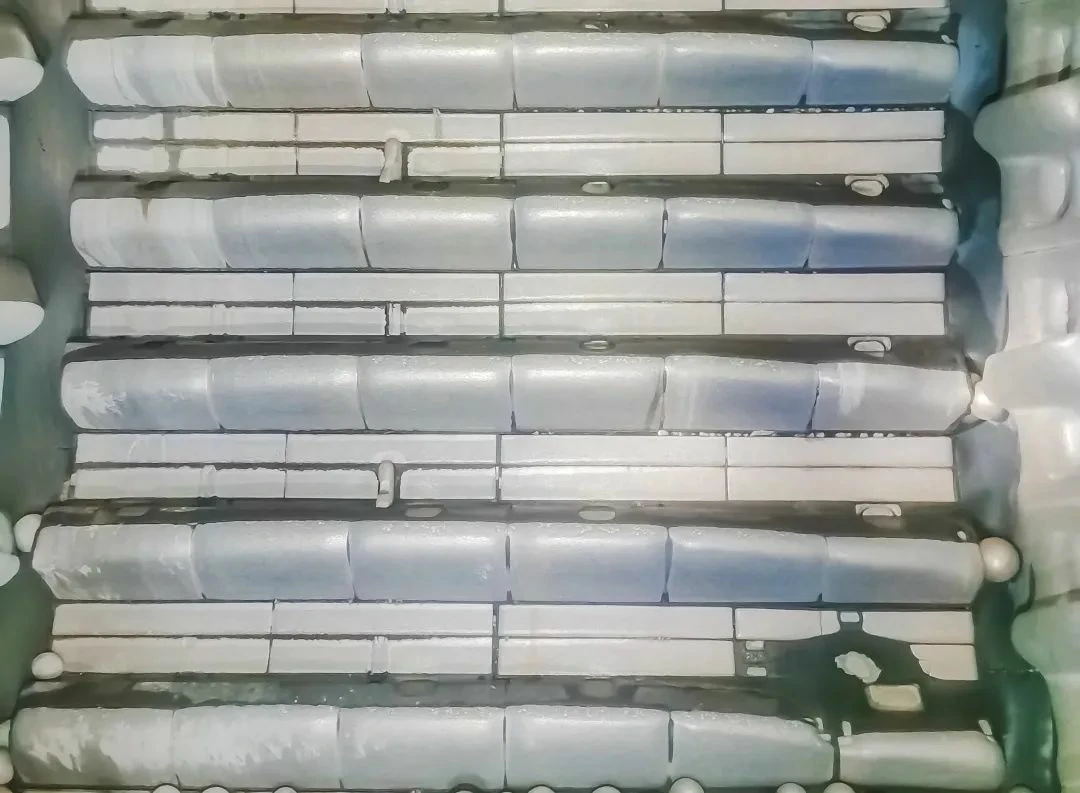

High alloy forged liner removed from the machine after 7 months of operation

Comparison Between High-Alloy Cast Grate Plate and Original Grate Plate |

|||

| Indicator Category | Original Grate Plate | High-Alloy Cast Grate Plate | Increase/Decrease |

| Unit Performance | 307.48 t/h | 335.37 t/h | 9.10% |

| Grate Plate Weight | 63 tons (gross) | 52 tons | -17.50% |

| Energy Consumption | 2743 kW | 2638 kW | -3.80% |

| Maintenance Frequency | Once every 2 days | Once per day | 50% |

| ——END—— | |||

High Alloy Forged Lining

Customer choice speaks for itself

“The service life of traditional metal liners is only about 4 months. Frequent replacement of liners will not only reduce the operating time of our equipment, but also increase the safety risk of equipment maintenance. The effect of this set of high-alloy forged liners is still very significant! It solves a major pain point in our equipment management. It has been running stably for 7 months. We can reduce the maintenance time by 3 days throughout the year. It is conservatively estimated that the economic benefits can increase by more than 5 million yuan throughout the year!”

——Feedback from a customer of a mineral processing plant in Tibet