WS Dredging Pump

WS series dredging pumps are newly developed sludge pumps, researched and manufactured by our company based on advanced technologies introduced from both domestic and international sources, aiming at the dredging and damming of rivers and seas. From practical experience at home and abroad, it is widely recognized that dredging pumps are the main equipment for river and sea treatment. This method is considered environmentally friendly, highly efficient, and energy-saving, without causing secondary pollution.

WS pump is a single-stage, single-suction, cantilevered horizontal centrifugal pump with advantages such as light weight, excellent wear resistance, and superior dredging performance. It is perfectly suited for use throughout the entire dredging process and offers significant overall economic benefits. It fully meets the requirements of dredging operations.

The pump mainly consists of the pump head, a gearbox specifically designed for the dredging pump, a high-elastic coupling, and a control and monitoring system for the drive unit. Highly wear-resistant cast alloy iron, with a hardness of no less than 58 HRC, is adopted for the impeller, front liner, and rear liner of the wet parts. The pump casing is made of wear-resistant alloy steel, designed to withstand pressure and abrasion.

As part of EMAC, PumpMac provides abundant premium pump-driven power pack options, including WPT PTO, Advance gearboxs, and pump head, as well as customized water pump sets. We also offer a set of NFPA 20 standard engine power pack accessories, including air intake shut-off valves, DC contactors, engine control panels, jacket water heaters, and more. We provide full life cycle services for all customers, from design to power system supply, from installation to commissioning, from after-sales service training to spare parts supply, and from troubleshooting to overhaul technical support.

Our company can select different kinds of materials according to different media to meet specific dredging requirements. If you are in need of an engine model that is not currently available on our website, please contact the EMAC sales team for technical details and related documents. Our well-trained sales and engineering teams will assist you with all products and technical documents available here at Naipu Pump.

General Specifications of WS Series

| Flow range: | 180~25000 m³/h |

| Head range: | 20~85 m |

| Speed range: | 180~1400 r/min |

| Maximum allowable power: | N/A |

WS Model Description

- 300WS(G)

- 300 : Outlet diameter of dreging pump (mm)

- WS : Dredging pump

- G : high-head of dradging pump

- Aiming at the dredging and damming of the river and seas.

- Mainly consists of the pump head, gearbox specifically for the dredging pump, high elastic coupling and supervisor system of the driving device for the dredge

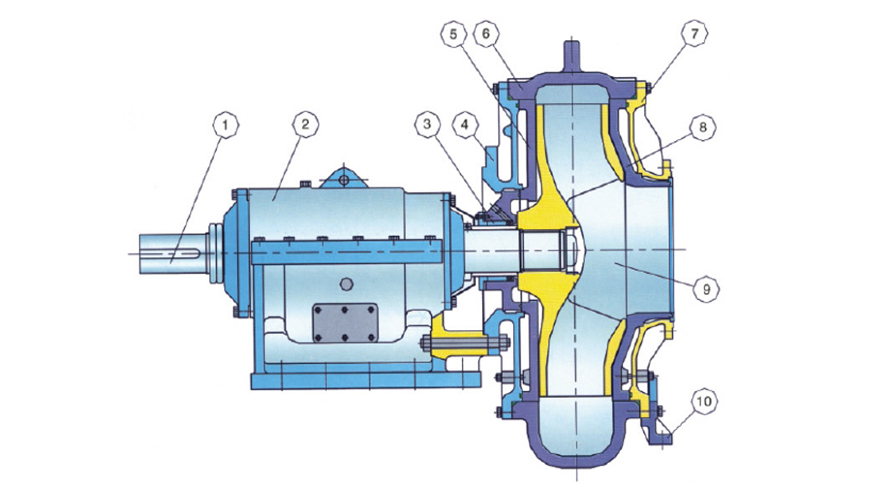

Construction Drawing for Type WS(G)

| NO | Part Name |

| 1 | SHAFT |

| 2 | FRAME |

| 3 | MECHANICAL SEAL ASSEMBLY |

| 4 | CONNECTING PLATE |

| 5 | REAR LINER |

| 6 | PUMP CASING |

| 7 | COVER PLATE |

| 8 | IFRONT LINER |

| 9 | IMPELLER |

| 10 | SUPPORT |

|

ParameterType |

Flow Rate (Q) |

Head (H) |

Speed (n) |

Efficiency (η) |

Impet Diameter |

Outlet Diameter |

NPSH (r) |

Max. Diameter of Flowed Partcle |

Pump Weight |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Five Pieces | Three Pieces | ||||||||||||

| m³/h | m | r/min | % | mm | mm | m | T | ||||||

| 100WS | 180 – 250 | 25 – 45 | 1000 – 1400 | 50 – 58 | 150 | 100 | <3.5 | 50 | 82 | 0.5 | |||

| 150WS | 250 – 550 | 20 – 40 | 1200 – 1400 | 58 – 60 | 200 | 150 | <4 | 76 | 127 | 1.1 | |||

| 150WSG | 350 – 700 | 40 – 65 | 800 – 980 | 68 – 71 | 200 | 150 | <3.5 | 84 | 140 | 1.9 | |||

| 200WS | 350 – 700 | 20 – 45 | 700 – 980 | 60 – 65 | 250 | 200 | <4.5 | 105 | 178 | 2.3 | |||

| 200WSG | 550 – 1000 | 40 – 65 | 700 – 850 | 70 – 72 | 250 | 200 | <4 | 108 | 180 | 3.2 | |||

| 250WS | 700 – 1100 | 20 – 45 | 500 – 750 | 65 – 70 | 300 | 250 | <4 | 132 | 220 | 4.5 | |||

| 250WSG | 900 – 1500 | 40 – 60 | 500 – 650 | 70 – 74 | 300 | 250 | <4.5 | 86 | 144 | 4.6 | |||

| 300WS | 1100 – 1800 | 20 – 40 | 400 – 600 | 65 – 68 | 350 | 300 | <4.5 | 144 | 241 | 5.5 | |||

| 300WSG | 1500 – 2200 | 30 – 65 | 400 – 550 | 74 – 78 | 450 | 300 | <4 | 144 | 241 | 8 | |||

| 350WSG | 2000 – 3000 | 40 – 65 | 400 – 550 | 74 – 78 | 450 | 350 | <4 | 147 | 245 | 8.8 | |||

| 450WSG | 3000 – 4000 | 35 – 67 | 350 – 500 | 76 – 80 | 600 | 450 | <4.5 | 125 | 254 | 12 | |||

| 500WSG | 4000 – 5500 | 40 – 65 | 350 – 450 | 78 – 80 | 650 | 500 | <4.8 | 150 | 250 | 17 | |||

| 600WSG | 5000 – 9000 | 55 – 80 | 320 – 400 | 81 – 85 | 650 | 600 | <6 | 160 | 220 | 30 | |||

| 700WSG | 8000 – 12000 | 60 – 85 | 280 – 380 | 83 – 85 | 750 | 700 | <6 | 180 | 280 | 50 | |||

| 800WSG | 10000 – 15000 | 50 – 70 | 260 – 360 | 79 – 80 | 850 | 800 | <6 | 200 | 300 | 70 | |||

| 900WSG | 12000 – 16000 | 50 – 75 | 280 – 330 | 83 – 85 | 950 | 900 | <6 | 210 | 320 | 95 | |||

| 1000WSG | 16000 – 25000 | 23 – 76 | 180 – 290 | 85 – 97 | 1100 | 1000 | <6 | 230 | 350 | 130 | |||

| ——END—— | |||||||||||||

| 1. “RU” : rubber , “M” alloy wear-resistant material. 2.Capacily range recommened : 50%Q'<Q<110%Q’ ( Q’≈Appropriate to capacily at highest officiency point ) 3.NPSH : Appropriate to point Q recommended at highest speed. |

|||||||||||||

Note: Max. Diameter of Flowed Particle includes two sets of data: Five Pieces and Three Pieces.

WS Series Dredging Pump

This list including all models of WS Series Dredging Pump.

Click here to find pump by type (head and flow rate).

Products Not Available

The relevant products still under developing or waiting to be update, please contact our sales team for latest updates.

![Deeply Cultivate the International Market, Empowering the Future of Rail ——Focus [PROMotion Expo 2025] SinoMac Exhibition Highlights Review](https://slurry-pump.com/wp-content/uploads/2025/09/Deeply-Cultivate-the-International-Market-Empowering-the-Future-of-Rail-——Focus-PROMotion-Expo-2025-SinoMac-Exhibition-Highlights-Review.webp)